In the chemical industry where safety risks are ever-present, protection at every level is paramount. The steel rolling door, renowned for its exceptional strength, sealing capabilities, and reliability, has become an indispensable asset for ensuring safe operations in chemical plants.

Why Choose Steel Rolling Doors?

High-speed steel rolling doors, made of high-strength, rigid materials and a sealed design, effectively isolate hazardous areas in chemical plants. For example, separating chemical storage areas from production areas with explosion-proof doors effectively prevents fires or explosions from spreading from one area to another. In the event of an incident, high-speed rolling doors can quickly close, minimizing the spread of danger and protecting other areas.

1.Reduced risk of explosion spread

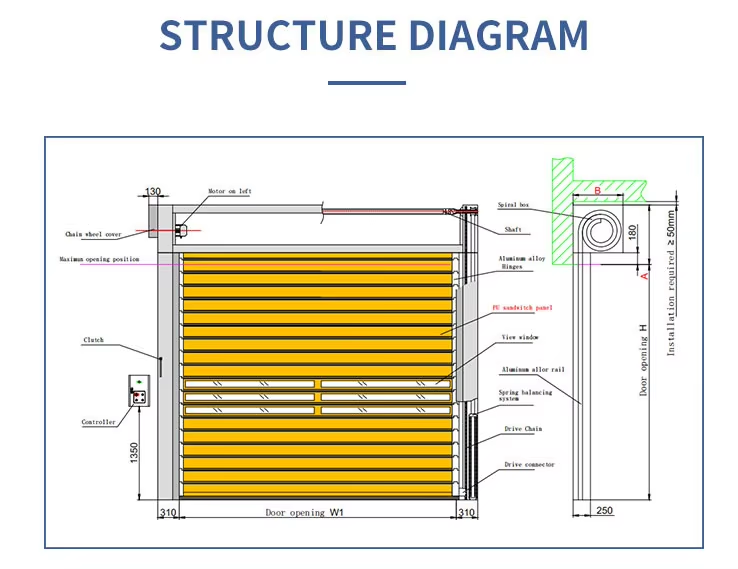

The door is made of double-sided colored steel panels with polyurethane foam sandwiched between them. This special structure makes it not only flame retardant but also anti-static. As a chemical workshop door, it has a good isolation effect and reduces the risk of explosion spreading. It can greatly improve the safety performance and reduce the potential risk from fire and static electricity.

2. Superior Sealing, Zero Leakage

The combination of a precision spiral guide track and high-quality sealing strips ensures a tight seal between the door curtain and frame. This effectively contains toxic, harmful, flammable, or explosive gases and dust, safeguarding personnel and the environment.

3. High-Speed Operation, Rapid Isolation

In an emergency, the door can open or close rapidly, enabling instantaneous isolation of hazardous areas. This critical speed provides invaluable time for emergency response, minimizing potential damage.

4.Heat and Corrosion Resistance

The production environment in chemical workshops is often high temperature and corrosive. The explosion-proof rigid speed door is made of heat and corrosion resistant material, which is able to operate stably for a long time in such environment. It not only ensures the structural stability of the door body. But also maintains a good seal in the corrosive gas of chemicals.

5.Exceptional Durability & Corrosion Resistance

Steel panels treated with specialized coatings (e.g., powder coating, galvanization) offer excellent resistance to corrosion from chemicals, acids, alkalis, and solvents common in industrial environments, ensuring long service life.

6.Enhanced Safety

The rapid door is equipped with a variety of safety protection devices, such as infrared sensors, airbags and so on. It can ensure the safety of personnel entering and leaving. Reduce the probability of accidents and protect employees and facilities.

7.Fast after-sales service

In the event of failure, the explosion-proof fast door manufacturers are required to provide a rapid after-sales response. Timely help enterprises to quickly find manufacturers for after-sales processing, will not encounter after-sales situation.

Core Application Scenarios:

Explosion-Proof Area Isolation: Physically isolates high-risk process areas and areas surrounding reactors from personnel work areas and evacuation routes.

Chemical Warehouse: Controls the entry and exit of personnel and materials to prevent the spread of fire and vapors.

Hazardous Materials Storage Room: Encloses and stores flammable liquids, high-pressure gas cylinders, or toxic substances.

Fire Zone: Serves as an effective fire barrier, slowing the spread of fire and smoke.

HEXION is a high-end brand in China specializing in high-speed rolling doors. Its products are sold well both domestically and internationally, and have become the preferred brand for workshop doors for foreign-invested enterprises, joint ventures, large state-owned enterprises, and strong private enterprises.

For more information about the company's products, please visit its official website: www.hexiondoor.com